About Us

About Us

It gives us an immense pleasure in introducing ourselves as one of the leading Manufacturing and Exporting Unit of Joints. Orthopaedic Implants and Surgical Instruments based in Ahmedabad, acquiring National Accreditations such as CDSCO( FDA) license unit set up to offer the products to end users at a very reasonable rate thus setting a benchmark in this particular field.

Right from importing the best of the Raw Materials and developing it in our own in house State of the Art Infrastructure equipped with the latest of the Machineries and operated by our skilled Operators thereafter forwarded to our efficient Quality Control Department for a initial check up and re forwarded for a final check up, neatly packed,labelled ,stocked, distributed as per timing all these is done with utmost care and due attention is paid to the

Why SMPL

- Honesty

- Discipline

- Teamwork attitude

- Commitment to our principal

- Good after sales service

- Easily communicable and accessible

minutes of the details which have earned us laurels not only from our domestic network of customers but overseas as well and we strive each day in and day out that the highest standard is maintained throughout. providing service at par is what we believe in and our official and marketing staff are always on their toes to render it any time asked for.

Participating in national and International Conferences, Exhibitions, Tenders, Government Hospitals and lots of such activities have strengthened us enough that we are confident in delivering the best to our customers as we learn a lot and not just stop there but infect implement on the new Designs, Services, Quality and Quantity based works, adapting to the latest technologies and introducing novel products wherein we hope to exceed customers satisfaction.

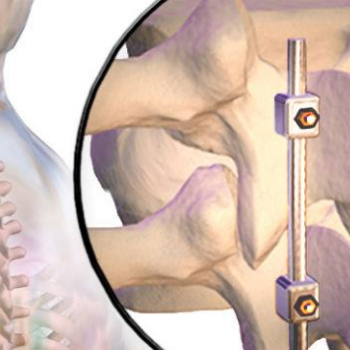

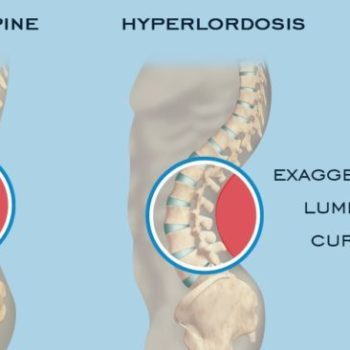

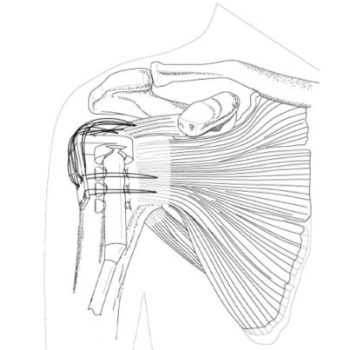

Our Trauma Implants, Spine System , Locking Plate System ,Nailing System, Hip and Knee System are our specialities which are in use nationally and globally and have worked wonders as per the Surgeons suggestions and we definitely will strive even more to offer goal oriented results in our future endeavours .

Our Vision

To be the market leader in Orthopadic Implants and Instruments segment by adopting innovative and proven technologies ensuring customer delight.

Our Mission

To provide world class Orthopedic products, which are of high quality, affordably priced, that contributes to the wellness of the patients, and positively impact both our clients and organizations growth.

Key Priorities

- Drive Superior Result

- Delight Our Customers

- Protect And Enhance Our Brand

- Develop Our People

Our milestones are a reflection of our commitment to this enduring journey.

Our journey through the decades

A company which has assimilated total quality philosophy and which is not selling product to clients but causing them gaining health. The principle objective would be to forecast the changes in the business environment, as India is a vast country of One billion people, with full of diversities. A country where a Mercedes Benz Car and a Bullock Cart share the same road. This type of environment is to be taken into account for making a decision on business in India. We aim to provide our quality products at the lowest price.

Started company with vision

Expanded factory with 2 more production plant

Supplied to 500+ networks in 20+ countries

Started Corporate House

Team : Backbone Of The Company

Our team consists of marketing analysts, QC personnel and other professionals who are always ready to meet the challenging requirements of the clients. The professionals keep themselves abreast of the requirements of hospitals, clinics and entire medical fraternity requiring Orthopedic Implants and accordingly procures the best range catering to the distinctive requirements.

Quality : What Separates Us

As an internationally certified business entity, we pay close attention to quality at each level of operations. Starting from approval of samples to the delivery stage, we ensure that the products sourced and delivered by us are the best in terms of designing efficiency, durability, wear resistance and meet the industry standards.

Packaging : Assuring Safety

We also ensure suitable packaging and labeling of the products to ensure their safety during handling, delivery and storage

What They Are Saying

100% Recommended

We are managing Manufacturer Smit Medimed since numerous years and we are without question happy with the collaboration, the quality and the execution of our agreements, So we just recommend to work with Smit Medimed.

Fast Solutions

We value the orthopedic items made by Smit Medimed. Their quality has been reliably unrivaled without any grumblings from our patients. Smit Medimed orthopedic inserts and instruments are the best in the Subsequent to experimenting with different organizations items we have at last chosen to stick to items fabricated and provided by Smit Medimed.

Great Material

We are cooperating with Smit Medimed and they give us great help and great material and our prosperity is their value, great market, backing and we complete with the astounding brand.